Food Mill Guide

Essential tools for smooth purees, fluffy mashed potatoes, and seedless sauces

Food mills are indispensable culinary tools that bridge the gap between a sieve and a blender, offering a unique texture that mechanical processors simply cannot replicate. By crushing and forcing soft foods through perforated plates, food mills separate skins, seeds, and fibers from the pulp, resulting in smooth purees, fluffy mashed potatoes, and seedless sauces. Whether you are a high-volume commercial kitchen processing bushels of tomatoes or a restaurant chef perfecting a root vegetable puree, understanding the types, sieve sizes, and capabilities of food mills is key to achieving professional results.

How Do Food Mills Work?

Food mills come in a variety of shapes and sizes but their general use is the same. With either manual cranking or an electric motor, food mills forcefully crush soft foods and force them through a series of perforated plates.

Plates, sometimes also referred to as discs, are interchangeable and allow for varying thicknesses of the end product. This ultimately separates the solid parts of the fruit and vegetables (like the seeds and skin) and collects all of the more desirable parts like the bulk of a potato or fruit juices.

Food Mill vs. Sieve

A food mill may sound very similar to a strainer or sieve but their end result is quite different. Sieves only give you the bare minimum of juice, and the fruit or vegetable must first be broken down to collect it. On the other hand, food mills bring all the muscle and do the breaking down for you. Food mills are great for things like mashed potatoes and thick tomato juices whereas a sieve is good for draining pasta or creating a pulp.

What Is a Food Mill Used For?

While versatile, food mills excel in specific applications where texture control and waste separation are paramount.

Mashed Potatoes

The food mill is widely considered the best tool for making mashed potatoes. Unlike food processors, which rupture starch cells and create a gummy, glue-like paste, a food mill gently extrudes the cooked potato. This preserves the starch structure, resulting in a light, fluffy, and airy texture that is preferred in fine dining.

Tomato Sauces & Marinara

For making fresh tomato sauce, a food mill acts as an all-in-one peeler and seeder. Cooks can boil whole tomatoes and run them through the mill; the flesh passes through as a smooth puree, while the bitter skins and seeds are caught by the sieve, saving hours of prep time compared to blanching and peeling by hand.

Purees, Soups & Baby Food

- Fruit Coulis: Separates raspberry or blackberry seeds from the pulp for smooth dessert toppings.

- Creamy Soups: Processes fibrous vegetables like celery or leeks into smooth bases without the need for straining afterwards.

- Apple Sauce: Cooks can process whole cooked apples (skins on) to extract the maximum amount of pectin and flavor before separating the skins.

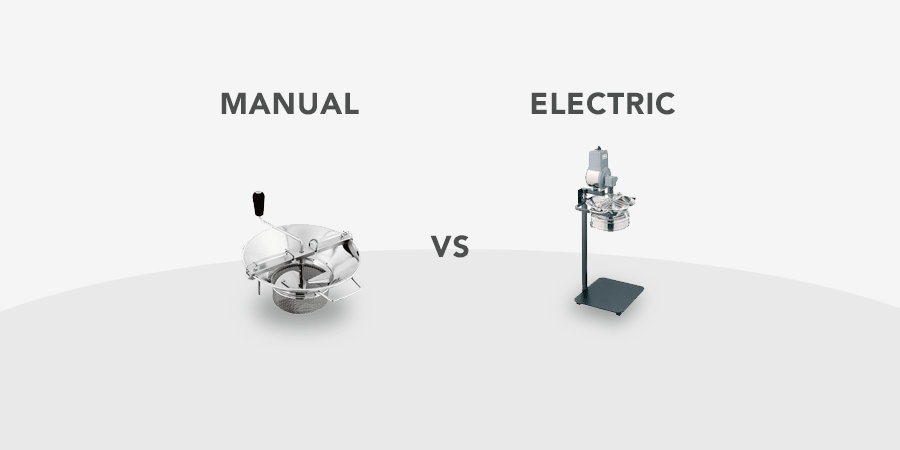

Types of Food Mills

Commercial food mills are categorized by their power source and intended volume.

Manual Food Mills

The classic design found in most professional kitchens. These are operated by a hand crank and are ideal for small to medium batches or precise finishing work.

- Best For: Mashed potatoes, finishing soups, small batches of sauce.

- Capacity: 1 to 5 lbs per minute (depending on operator speed).

- Features: Mounts onto mixing bowls or pots; interchangeable grids.

- Pros: Precise control, no electricity needed, portable, lower cost.

- Cons: Labor-intensive for large volumes.

Electric Food Mills

Electric food mills replace the hand crank with a powerful motor, allowing for continuous, high-volume processing without operator fatigue. These units typically stand on legs or mount securely to large vessels. Many commercial electric models feature a Continuous Feed design with an open chute, allowing operators to process unlimited batch sizes directly into a secondary container without stopping to empty the bowl.

- Best For: High-volume production kitchens, canning operations, large-scale tomato processing.

- Capacity: 10 to 20+ lbs per minute.

- Features: High-torque motors, continuous feed chutes, heavy-duty stands.

- Pros: Extremely fast, reduced labor costs, consistent output, unlimited batch capacity (continuous feed).

- Cons: Higher initial investment, requires electrical connection, takes up more storage space.

Tomato Squeezers

A specialized subtype of the electric food mill, tomato squeezers are engineered specifically for separating tomato juice and pulp from skins and seeds. They use a screw-drive (auger) mechanism rather than a crushing blade.

- Best For: Italian restaurants making daily sauce, canning facilities.

- Mechanism: An auger pushes tomatoes through a conical sieve.

- Pros: Maximum yield extraction from tomatoes.

- Cons: Less versatile than standard food mills (not ideal for potatoes).

Understanding Sieve & Grid Sizes

The versatility of a food mill comes from its interchangeable perforated bottom plates (sieves or grids). Selecting the right hole size is critical for the desired texture.

| Preview | Size (mm) | Size (inch) | Best Applications |

| 1 mm | 3/64" | Works well for syrups & juices. Blocks all seeds. |

| 1.5 mm | 1/16" | Works well for purees, soups, and sauces. Blocks tomato seeds. |

| 2 mm | 3/32" | Works well for mashed potatoes & other mashed vegetables. Blocks most seeds. |

| 3 mm | 1/8" | Works well for overall mashing. Allows small seeds to pass. |

| 4 mm | 3/16" | Works well with stringy vegetables. Allows seeds to pass. |

Buying Tip: Most commercial food mills come with a standard 3mm or 4mm grid. Smaller 1mm or 1.5mm grids often need to be purchased separately as accessories.

Selecting the Right Food Mill

Capacity & Flow Rate

- Home/Light Duty: 1-2 lbs/minute. Suitable for 5-10 quart batches.

- Standard Commercial: 3-5 lbs/minute. Suitable for 10-40 quart batches. Look for models with wide hooks that allow them to sit securely on top of standard commercial stock pots.

- Heavy Duty Electric: 10+ lbs/minute. Necessary for operations processing cases of produce daily.

Material Construction

- Stainless Steel: The industry standard. Durable, non-reactive (safe for acidic foods like tomatoes), dishwasher safe, and NSF certified.

- Tin-Plated: Traditional but less common now. Reactive to acids (can impart metallic taste to tomatoes) and not dishwasher safe. Recommendation: Stick to 18/10 Stainless Steel for commercial use.

Maintenance & Care

- Clean Immediately: The most important rule for food mills is to wash them immediately after use. Once starch (potatoes) or fruit fibers dry in the small perforated holes, they become like cement and are extremely difficult to scrub out.

- Disassembly: Fully disassemble the crank, spring, and blade mechanism after every shift to clean the center post where food can get trapped.

- Blade Tension: Over time, the spring that pushes the blade against the sieve may lose tension. Check this periodically; if the blade doesn't sit flush against the plate, it won't mill effectively.

Frequently Asked Questions

Food Mill vs. Food Processor: Which is better?

For texture and separation, the food mill wins. Food processors chop everything (including seeds and skins) into a paste and can turn potatoes gluey. Food mills separate the waste and preserve the cellular structure of the food for a fluffier result.

Can I use a food mill for mashed potatoes?

Yes, it is the preferred tool for professional chefs. Use a 2mm or 3mm disc for the fluffiest results. Ensure potatoes are fully cooked and hot when milling.

Food Mill vs. Potato Ricer: What's the difference?

A potato ricer is excellent for mashed potatoes but is a "unitasker" - it only does one job. A food mill achieves the same fluffy texture for potatoes but is a multitasker that can also process sauces, soups, and jams. If you only make mashed potatoes, a ricer is fine; for everything else, get a mill.

Do I need to peel vegetables before using a food mill?

Generally, no. One of the main benefits of a food mill is that it separates skins from the pulp. However, for large items like potatoes, peeling beforehand can speed up the process if you don't want to stop frequently to clear skins from the basket.

How do I stop my food mill from clogging?

If skins and seeds build up and block the holes, simply turn the crank in the opposite direction (counter-clockwise) for a few rotations. This lifts the blade and scrapes the debris up from the bottom plate, clearing the holes so you can resume milling.

Can I use a food mill for blackberries and raspberries?

Yes, but you must use the finest grid available (1mm or 1.5mm). Berry seeds are very small and will pass through standard 2mm or 3mm discs. Using a fine disc is the best way to create smooth fruit coulis and jams.

What sieve size should I use for tomato sauce?

A 1.5mm or 2mm sieve is ideal. It removes all skins and most seeds while allowing the rich pulp to pass through.

Shop Food Mills

- Commercial Food Mills - Manual and electric options for all volumes

- Food Mill Grids & Sieves - Interchangeable discs for texture control

- Tomato Squeezers - Specialized electric units for sauce production

Related Guides

- Commercial Mixer Guide - For doughs and batters

Share This!